Cr

Thin Dense Chrome

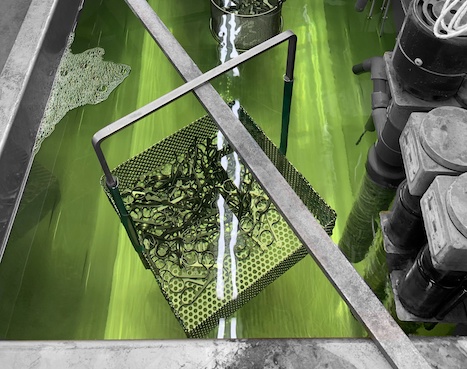

Electrolizing - Thin Dense Chrome

Chrome plating is an electrochemical process that bonds a chromium layer directly to ferrous and non-ferrous base metals with no flaking, cracking, or peeling. The chromium surface layer has a hardness of 68-72 Rc and increases wear resistance, reduces friction, prevents galling and seizing and minimizes corrosion.

Electrolizing is a proprietary, validated thin dense chrome coating process. For Medical Applications, ECO recommends our proprietary medical chrome coating: MEDCOAT 2000™

Capabilities:

- Different Thickness Depending on Application

- Masking for Non-Coated Areas

- Variety of Finishes Including Dull Non-Reflective

- Heat Treatment for Hydrogen Embrittlement

- Passivation and Electropolish Preparation

- Thickness Measured by XRF

Benefits:

- Will Not Chip, Flake, or Peel

- Increased Hardness – 68-72 Rc

- Lubricity (Reduced Seizing & Galling)

- Corrosion Protection

- Wear and Abrasion Resistance

Specifications:

- AMS 2460

- ASTM B-177

- ASTM B-254

Example Applications:

- Aircraft Components

- Nuclear Power Generation Components

- Military Vehicle Components

- Gears

- Axles

Important Considerations:

- Material

- Buildup per Surface

- Masking

- Racking

ECO can provide guidance on each of these items relative to your specific parts.

Quoting Information

Always request a quote prior to sending an order. To facilitate the quoting process, please include a part drawing and processing specification if applicable. If the drawing and/or specification do not identify the following, please provide: substrate material, plating thickness range, critical areas for plating, masked areas if required, and optional areas if applicable. Typical lot size and annual volume are also helpful for quoting. To achieve optimum performance and cost-effectiveness, all coating requirements should be reviewed with ECO prior to processing.

For maximum protection against damage and corrosion, before and after processing, all parts must be properly wrapped, preserved, and shipped in suitable containers. Parts need to be free of scale, rust, and corrosion prior to processing. ECO will remove oil, grease, and other preservative materials. Parts will be returned in same packaging used to ship parts to ECO.